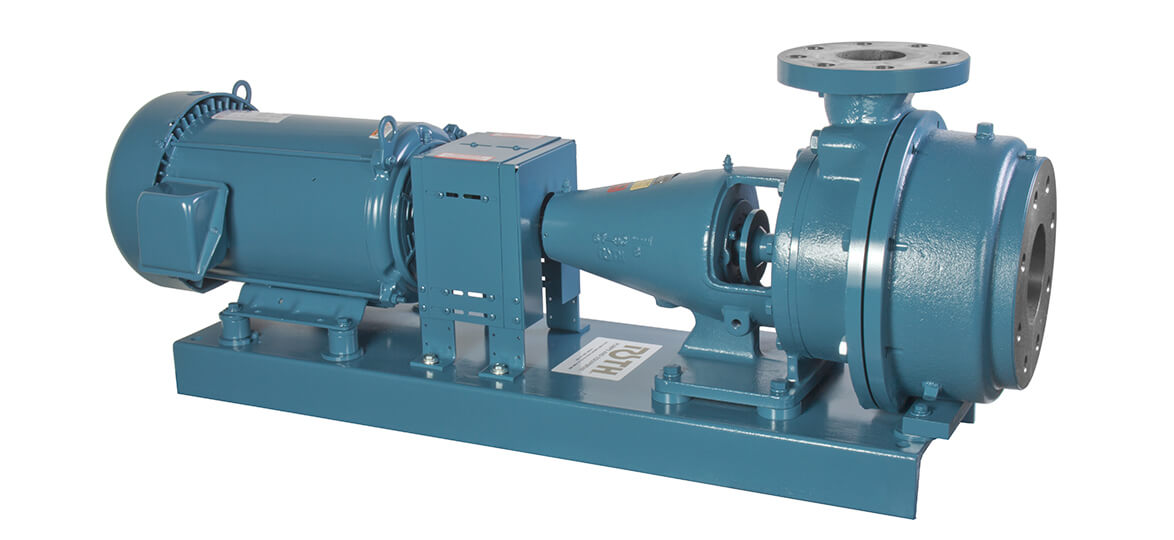

Low NPSH Pumps for Boiler Feed and Industrial Applications

Developed to pump 230˚F deaerated water from the deaerator to the boiler. This original design has now been improved to include high capacity models fully functional at one foot NPSH. Our Low Net Positive Suction Head (NPSH) pump is specifically designed for industrial applications where low NPSH conditions are critical. Engineered to handle challenging suction situations, this pump minimizes the risk of cavitation, ensuring smooth operation even in low-pressure environments.

The Roth Pump Company is the only pump manufacturer in the world today that offers a line of pumps with full performance at one foot NPSH at speeds of both 1750 and 3500 RPM in a range of differential heads up to 600 feet TDH, capacities up to 190 GPM. All Roth pumps in this bulletin are guaranteed to deliver full rated capacity of boiling water to the boiler with only one foot NPSH.

ROTH TURBINE DESIGN INCREASES THE CENTRIFUGAL'S PRESSURE AND LOWERS THE OPERATING SPEED

The regenerative action turbine pump takes over where the centrifugal stops. Following are those areas in which the ROTH turbine pump surpasses the conventional centrifugal pumps:

More and more engineers are specifying "centrifugal or turbine" pumps for application within range up to 200 GPM and up to 300 PSI in order to permit cost and performance comparisons with conventional centrifugal pumps.

In such cases it is recommended that electric motors for drivers be specified as "non overloading at design point with overload and under voltage protection." This permits consideration of smaller motors when the pump selected has improved efficiency.