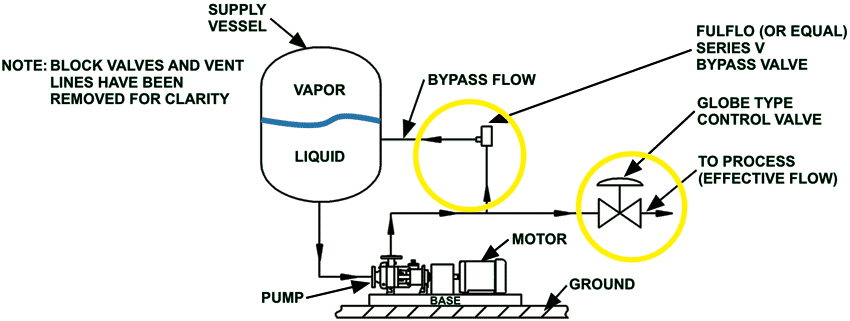

Flow Schematic

Control and use of Roth Pumps as represented on effective performance curve with flow schematic. (Drawing A-5304).

- Schematic shown is intended for process flow control, not a piping schematic.

- Roth will review customer’s proposed piping drawings upon request or will supply a suggested piping schematic. At a minimum, a piping drawing would usually incorporate means necessary to isolate pumps (block valves), protect against overpressure (bypass valve and/or rupture disk) and vent lines.

- Flow schematic incorporates a standard globe body, diaphragm-operated control valve which will enable system to deliver from 0 GPM to full pump capacity (for the condition shown on curve, full capacity would be 24 GPM at assumed differential pressure). Control valve recommended supplier.

Fisher Controls

Marshalltown, IA 50158

Phone: (641) 754-3011

- Pump input power [motor BHP (Brake Horse Power)] normally increases as flow rate decreases. When applying regenerative turbine pumps, the system designer should be aware that the use of a bypass valve (see below) solves this problem and allows the motor to be “non-overloading” (see effective curve).

Bypass Valve

The “key” to the entire system.

Combining a “bypass valve” with a regenerative turbine pump provides user with a system which delivers both the:

- High differential head of a positive displacement pump

- Moderately rising head/capacity curve of a centrifugal pump

- Results = stable flow conditions in the process.

Bypass valve settings are generally field adjustable. Valve is actuated by an increase in differential pressure (not total pressure). Valve cracking pressure is normally set 10% above the assumed design point. Valves are available in all common metals (316SS, steel, bronze, iron). Recommended supplier due to reliability, simplicity, and reasonable cost:

Fulflo Specialties Company

Blanchester, OH 45107

Phone: (937) 783-2411

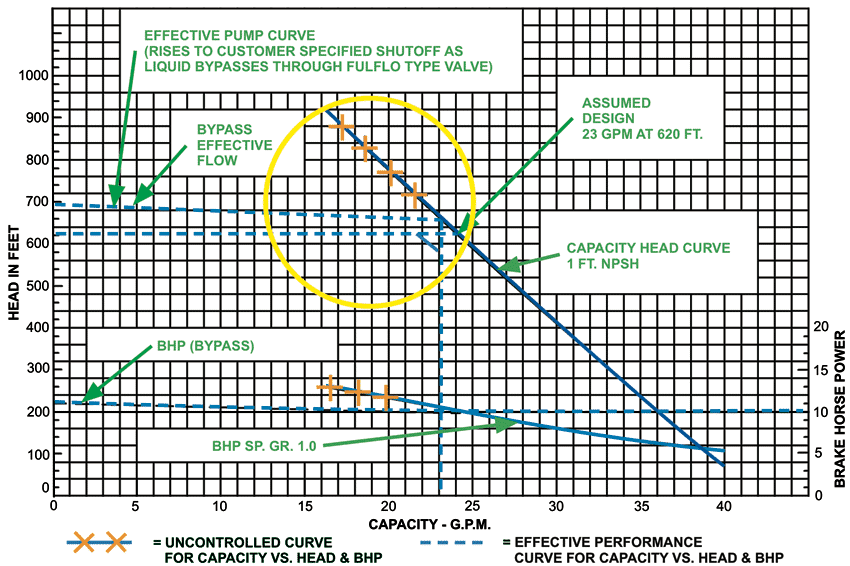

Pump horsepower is shown on the performance curve. Typical regenerative turbine pump BHP curve increases as flow decreases. Use of a bypass valve limits the BHP by limiting pump discharge pressure.

Effective Pump Performance

Effective pump performance curve should be compared to uncontrolled curve.

Uncontrolled curve is shown by blue line with X marks above bypass valve setting. Pump performance will follow blue line as pressure increases from zero to assumed design point; then it will follow the dotted line to a “zero effective flow” (flow to process).

The effective pump curve is one which shows:

High head, low flow and a wide operating range. (This range is desirable on many applications where the head may vary greatly or is hard to find.)

Slope of rising head/capacity curve that is gentle, modest, and continuously rising. (Exact amount of pressure rise is available from valve supplier.)

Pressure and BHP increase continuously to shut off.

Motor BHP limited to that corresponding to shut-off differential pressure.

Suggested Flow Control Schematic For Roth Regenerative Turbine Pump

Typical Regenerative Turbine Pump Curve With Fulflo Pressure Limit / Bypass Valve

Drawing No. A-5304

Download the PDF version of Positive Flow Control with Roth Regenerative Turbine Pumps