Why is the steam being vented / flashed?

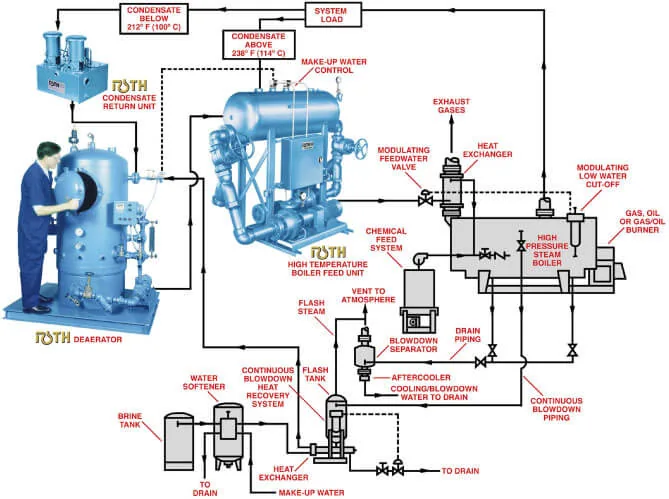

1. To lower the 238°F (114°C) condensate returns so that they may be deaerated.

2. To lower the temperature of the condensate so that the centrifugal pumps will work.

The above reasons are flawed.

If the condensate is above 238°F (114°C), it is already deaerated and that heat, and its associated fuel cost may be saved if returned directly to the boiler. The real problem is that as the temperature increases, centrifugal pumps stop pumping due to cavitation.

Roth One Foot NPSH Pumps are noncavitating at temperatures up to 400°F (204°C). The hotter the condensate that can be returned to the boiler, the less money is spent on fuel heating it back to boiling.