WHEN YOU SAVE CONDENSATE

You will:

- Reduce fresh water use

- Reduce amount of pretreatment required

- Reduce boiler chemical costs

- Reduce fuel cost to reheat 50°F water to 180°F – 220°F

- Reduce sewer system disposal costs from dumping raw condensate

When you save fuel

The highest potential reduction in energy use comes from efficiently returning hot condensate to the boiler. This reduces the amount of fuel that will be required to heat cold make-up water from 55°F to 180°F – 212°F. The energy in the condensate in a typical system can be more than 10% of the total steam energy content.

Why use a Roth condensate return unit?

Because steam traps are unreliable. When the steam trap fails 250°F steam enters the condensate receiver and the condensate goes boiling. The only NPSH available is the liquid height of the condensate.

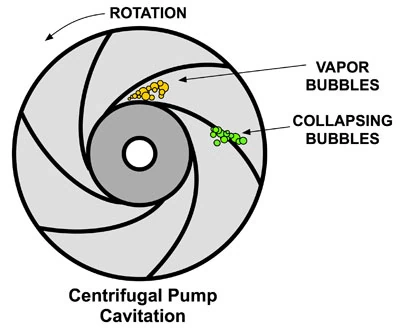

NPSH = Net Positive Suction Head. For a boiling liquid NPSH = the height of the liquid above the pump suction less any suction loses. If the NPSH required by the pump is greater then NPSH available, the pump will cavitate.

Cavitation occurs because of a low pressure spot in a centrifugal pump impeller. Bubbles will implode on the vanes of a centrifugal pump. A cavitating pump will have vibration, noise, seal failure, and a greatly reduced flow, making it unreliable. If the pump is not pumping at rated flow, the tank will overflow and drain with treated condensate water and heat hence, energy is being wasted.

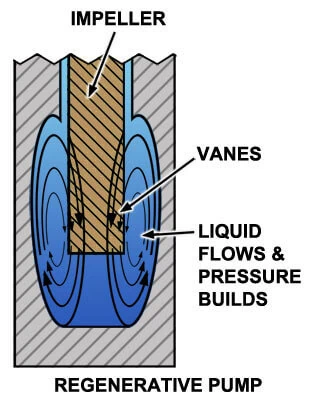

The Roth regenerative turbine pump difference

A Roth regenerative turbine pump requires only one foot of NPSH full curve to operate. Roth Regenerative Turbine pumps are noncavitating.

A regenerative turbine pumps forms two mini tornados inside the pump. Bubbles are pulled into the center of the tornado where they are compressed back into the liquid and do not implode. Roth condensate tanks are designed to provide one foot of condensate liquid height above the pump suction and do not have any mechanical seals below the water line. No tank draining is required for regular maintenance. Roth Pump condensate systems provide increased reliability as they are engineered and time tested to prevent cavitation. (They will continue to pump even with failed steam traps)

Stop dumping condensate and improve your plant’s energy efficiency easily with Low Maintenance & Reliable Roth Pump Condensate Return Units.